About Alp

Artificial Lift Performance (Alp) is now part of ChampionX. Combining the capabilities of Alp’s flagship Pump Checker™ software with ChampionX’s XSPOC™ production optimization software delivers a comprehensive suite of advanced analytics across all major artificial lift types and chemical applications, enabling operators to gain invaluable insights and make informed decisions to meet their business objectives.

Alp has been helping companies solve oil production and artificial lift problems since 2004. Based in Edinburgh, Scotland, Alp has extensive expertise in developing artificial lift optimization software designed to maximize production and extend the life of artificial lift equipment.

Situation

Having taught around 200 courses related to artificial lift and production optimization, people always loved the courses, but always said the same thing – “we don’t have time to do Optimization”.

Action

We decided to build software to automate well optimization, so that every well with artificial lift could be automatically analyzed, understood and operated efficiently.

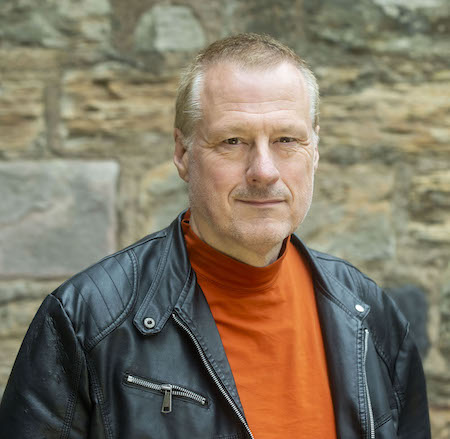

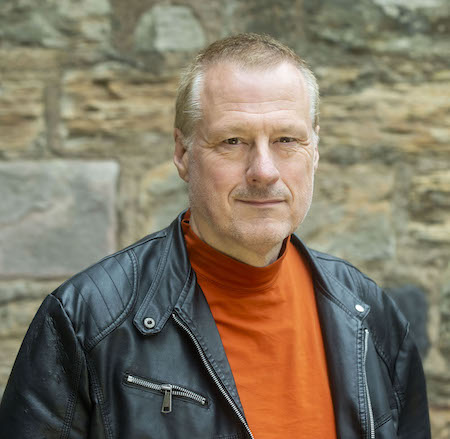

Meet the founder, Sandy Williams

The company was founded by Sandy Williams, an international consultant and trainer who has spent more than 30 years in the oil business working for organizations such as Amoco, Phoenix and Schlumberger and in markets across Africa, the Americas, Europe and the Middle East.

Our team

Fiona De Luca

Fiona is a highly motivated Business Leader with 25+ years of experience in driving commercial growth, and a strong track record in sales and operational management across a breadth of sectors. Skilled in leading projects / initiatives, implementing new processes and streamlining complex operations for maximum productivity.

Fiona is a highly motivated Business Leader with 25+ years of experience in driving commercial growth, and a strong track record in sales and operational management across a breadth of sectors. Skilled in leading projects / initiatives, implementing new processes and streamlining complex operations for maximum productivity.

An expert in directing teams and driving partnering activities for the development of new business and forging strong relationships with stakeholders. Well versed in working at a senior level to develop effective strategies and plans to meet corporate aims successfully.

Fiona enjoys walking in the hills in and around Stirling, has recently discovered wild swimming. She likes cooking and enjoys spending time with her daughter and husband.

Fiona De Luca

COO

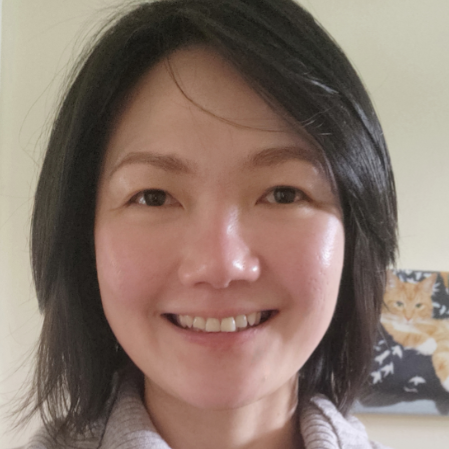

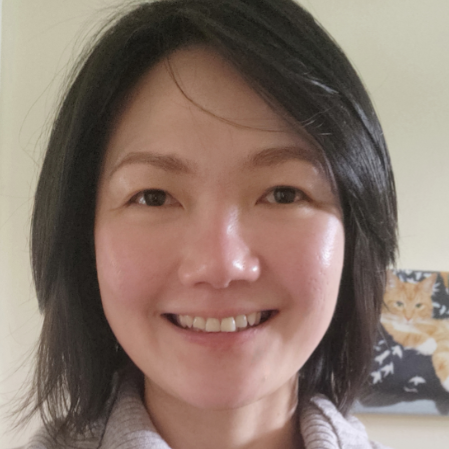

June Tee

Originally from Malaysia, June fell in love with Edinburgh the moment she exited Waverley Station back in 2004, when she first came to do her MSc Informatics (major in AI).

Originally from Malaysia, June fell in love with Edinburgh the moment she exited Waverley Station back in 2004, when she first came to do her MSc Informatics (major in AI).

Upon completing her MSc, she’s landed on her first permanent job in the medical imaging visualization area (after peeling 30kg of onions every day for a month at a restaurant while hunting for jobs).

She’s then moved on to work in travel and banking sectors, before finally settled with the oil and gas industry.

June loves all sort of racquet sports, especially badminton and tennis. She also enjoys hillwalking (and is a keen Munro bagger too!).

June Tee

Principal Engineer

Andy Nisbet

Andy has 20+ years of experience working on digital products and applications covering web, mobile, and hardware across a variety of sectors from start-ups to banking and local government. His role at ALP is to work across the teams to deliver enhancements and optimisations within Pump Checker.

Andy has 20+ years of experience working on digital products and applications covering web, mobile, and hardware across a variety of sectors from start-ups to banking and local government. His role at ALP is to work across the teams to deliver enhancements and optimisations within Pump Checker.

Outside of work he enjoys spending time with his family, swimming, cycling, and running, and “occasionally” completing middle distance triathlons and marathons.

Andy Nisbet

Product Manager

James Britvar

James has 8 years of industry experience across production and drilling operations. He was introduced to Artificial Lift Performance as an Engineer, for an independent E&P company starting to grow and optimize ESP operations in the Bakken.

James has 8 years of industry experience across production and drilling operations. He was introduced to Artificial Lift Performance as an Engineer, for an independent E&P company starting to grow and optimize ESP operations in the Bakken.

During that time Sandy and James co-authored and SPE185150-MS, a research paper sharing lessons learned and successes that resulted from implementing Pump Checker, and presented it at the 2017 ESP Symposium.

James has a developing role with ALP, helping customers achieve maximum value and obtain their production goals. His personal experience with Pump Checker will bring a new perspective to meeting client needs and expectations.

James is based out of Denver Colorado and during free time he enjoys the out of doors, fitness, and real estate investing. James recently started a family and has a baby daughter.

James Britvar

Production Optimization Engineer

Tom Swarbrick

Tom has 8 years of petroleum engineering experience working for both operators and consulting organisations within the Oil & Gas Industry. During this time, Tom has experienced implementing digital oilfield solutions for a number of assets across the globe, focused on surveillance, virtual metering and production optimisation.

Tom has 8 years of petroleum engineering experience working for both operators and consulting organisations within the Oil & Gas Industry. During this time, Tom has experienced implementing digital oilfield solutions for a number of assets across the globe, focused on surveillance, virtual metering and production optimisation.

Outside of work, Tom is pursuing a MSc in Computational Analytics from Georgia Tech and enjoys cycling around Scotland.

Tom Swarbrick

Production Optimization Engineer

Harun Zahid

Harun graduated with a MEng in Chemical Engineering just over five years ago and has since taken on a petroleum engineering role. This began with research into multiphase flow modelling before progressing to model building and calibration, field diagnosis and production optimization of the full oil and gas system, including fluid, reservoir, well and network.

Harun graduated with a MEng in Chemical Engineering just over five years ago and has since taken on a petroleum engineering role. This began with research into multiphase flow modelling before progressing to model building and calibration, field diagnosis and production optimization of the full oil and gas system, including fluid, reservoir, well and network.

In addition, Harun delivered a variety of physics based and problem solving training courses that help engineers to gain value through software based, physics and data driven solutions.

Outside of work, Harun enjoys being outdoors, is very active, loves to read and considers himself to be a bit of a foodie.

Harun Zahid

Production Optimization Engineer

Andy Brown

Andy Brown is a Digital Oilfield expert, working with large oil companies to small independents, bringing the financial benefits of the Digital Oilfield to the bottom line.

Andy Brown is a Digital Oilfield expert, working with large oil companies to small independents, bringing the financial benefits of the Digital Oilfield to the bottom line.

He has helped the industries’ leading Artificial Lift service companies develop new products and software for the Digital Oilfield globally.

When not chilling in Mallorca, Andy is learning to Bachata & Tango.

Andy Brown

Product Consultant

Peter Thurston

Peter Thurston is the Platform Team Lead at ALP with a Ph.D. in Artificial Intelligence and Neural Networks. In his 40+ years in the industry, Peter has ‘been around the block’; involved in a range of systems from speech recognition, telecoms, databases, and sophisticated web portals such as the PumpChecker system here at ALP. It was Doctor Who as a child and watching the Cybermen with Patrick Trouton that piqued his interest In computers and he maintains an ambition to build his own Cyberman (or DALEK, as they have no legs).

Peter Thurston is the Platform Team Lead at ALP with a Ph.D. in Artificial Intelligence and Neural Networks. In his 40+ years in the industry, Peter has ‘been around the block’; involved in a range of systems from speech recognition, telecoms, databases, and sophisticated web portals such as the PumpChecker system here at ALP. It was Doctor Who as a child and watching the Cybermen with Patrick Trouton that piqued his interest In computers and he maintains an ambition to build his own Cyberman (or DALEK, as they have no legs).

Out of work, Peter is a keen hill walker and is slowly making his way through the 227 Munros in Scotland. In fact, it was the mountains and the ever-so-small accident of buying a house that brought Peter to Scotland in the first place. Back at base, he is also a keen railway modeler, having reached the point in life where keeping a cool exterior is no longer of great concern.

Peter Thurston

Platform Team Lead

Jagoda Janeczek

Jagoda is a Business Management BSc (Hons) graduate with a consistent interest in data management and business analytics in the technology sector. Her strong management background and the developing interest in data engineering allows her to perform a coordinative role in the company.

Jagoda is a Business Management BSc (Hons) graduate with a consistent interest in data management and business analytics in the technology sector. Her strong management background and the developing interest in data engineering allows her to perform a coordinative role in the company.

Out of the office hours, Jagoda spends a lot of time outdoors, travelling and taking analogue pictures along the way.

Jagoda Janeczek

Product Analyst

Samuel Shum

Samuel Shum is a Software Engineer with BSc(Hons) in Chemistry. He then went on to graduate from CodeClan, his experiences there and volunteering in the Scottish Tech Army taught him systems development life cycle through various projects.

Samuel Shum is a Software Engineer with BSc(Hons) in Chemistry. He then went on to graduate from CodeClan, his experiences there and volunteering in the Scottish Tech Army taught him systems development life cycle through various projects.

Away from the computer, Sam enjoys photography and spending time with his daughter.

Samuel Shum

Software Engineer

Kate Smith

Kate Smith is a Support Analyst with a BSc in Computer Science. She has experience in working in applications support roles for both Oil & Gas services organizations and operators within the industry.

Kate Smith is a Support Analyst with a BSc in Computer Science. She has experience in working in applications support roles for both Oil & Gas services organizations and operators within the industry.

Away from work, Kate enjoys family camping trips, playing tennis and time spent cheering on her four young children in all their endeavors.

Kate Smith

Support Analyst

Wojciech Smigielski

Wojciech

Wojciech

Wojciech Smigielski

Software Developer

Reece Carr

Reece is a software engineer with a degree in Computer Science and over 2 years of industry experience. He is keen to improve his technical abilities while working on real products and providing value to customers. Outside of work, Reece is a member of multiple local bands and performs as both a guitarist and bassist. He has a strong passion for various genres such as classic rock and metal and enjoys attending live shows.

Reece Carr

Software Developer

How much production could you be losing?

The technology exists to identify gas-lift and ESP produced wells that are losing production as a result of an undiagnosed artificial lift problem. The ability to diagnose and rectify such issues can alleviate lost production. How much revenue could you be losing?